FabHELI

Collaborative project between Méca, Loiretech and Naval Group on optimized propellers made of composite materials.

Propellers made of composite materials are a technical solution of great potential but still underexplored by companies of civil and military shipbuilding industry. Indeed, increased performances can be expected thanks to:

- The use of lighter materials: reduced acoustic radiation, less important efforts on engine transmission shaft, reduced energy consumption

- The use of more adaptable and deformable shapes in comparison with metallic materials

The project entitled FabHELI involving Loiretech, Méca and Naval Group is supported by the DGA (the French Government Defence procurement and technology agency) and expertise of Bureau Veritas and AML. FabHELI aims at designing, manufacturing and testing in real conditions optimized propellers made of composite materials.

In the maritime sector, the design, the mechanical dimensioning and the monitoring of propellers made of metallic materials are ruled by performance standards and reference documents issued by classification bureaux. The first step of FabHELI project consisted of defining a design methodology for propeller adapted to composites materials. This activity had been carried out based on talks with Bureau Veritas. The validation method of the design uses standard tests and specific tests created during the project.

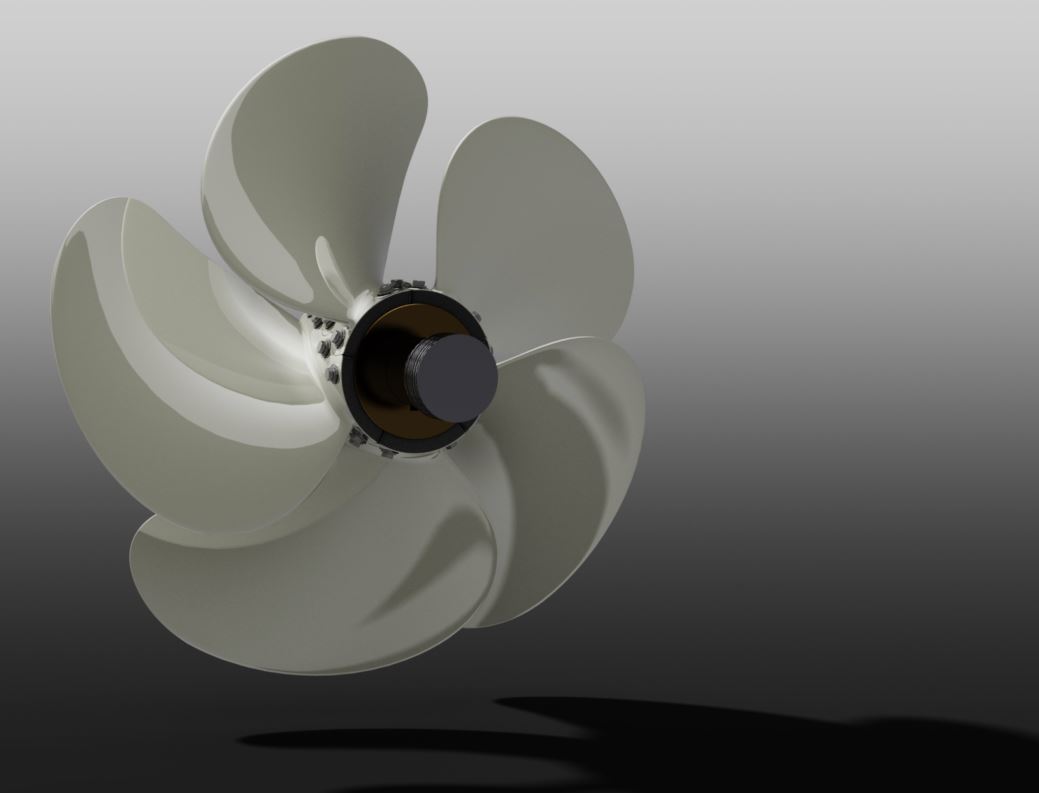

The second step of FabHELI project concerns the optimization of a manufacturing process enabling to realise propeller blades that where created thanks to the design methodology previously developed. The innovation remains in the solution of assembly of the blade and the hub as well as in the manufacturing process used : the RTM one-shot.

The third step consists of manufacturing the demonstrator and testing it. A propeller of 5 blades in composites where produced. This propeller of a diameter equaling 1.1m is to be assembled on a ship: the passenger boat named Le Palais which can transport 286 people. This boat weights 84 tons and measures 29m long. Real conditions testing at sea were carried out at full power to achieve 21 knots. The composite propeller is two times lighter than its metallic equivalent.

FabHELI project lasted 24 months and finished in 2018. Loiretech received an innovation award in Seoul (South Corea) in 2018: the JEC Asia Marine Innovation Award for the FabHELI demonstrator.