CERO

_______________________________________________

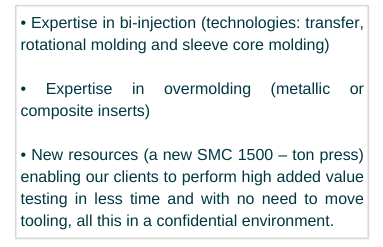

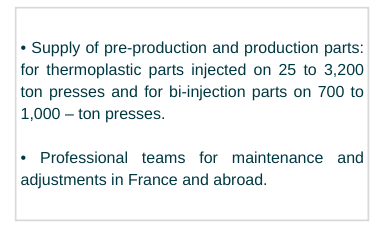

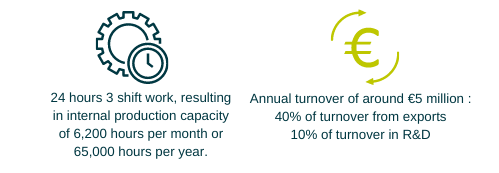

Design, manufacturing, testing and maintenance of industrial molds and tooling for thermoplastics and composites

- Mold and tooling design

- Manufacture of molds and tooling

- Press testing, provision of prototype and pre-production parts

- Modification and maintenance of molds and tooling

- Outsourcing

Contacts :

Address : CERO France, Parc d’Activités des Écobuts, 19 chemin des Halles, 85300 CHALLAN FRANCE

Phone : +33 2 51 49 79 10

Email : cerocontact[at]cero.fr

Website: www.cero.fr